GOCERAM

About |

GOCERAM (http://www.goceram.com) is based in Gothenburg (Göteborg) on the Swedish west

coast. The GOCERAM core business activities include development, manufacturing and marketing

of equipment systems in combination with production technology licenses for Medium Pressure Injection Moulding.

GOCERAM has invented the technology marketed since the year 1995 as Medium Pressure Injection Moulding technology which is covered by the main registered trademarks MEDPIMOULD® and CIModule® and several equipment trademarks, the generic processing technology is protected by a joint patent, related powder material patents and further patent protection is underway to cover selected product segments.

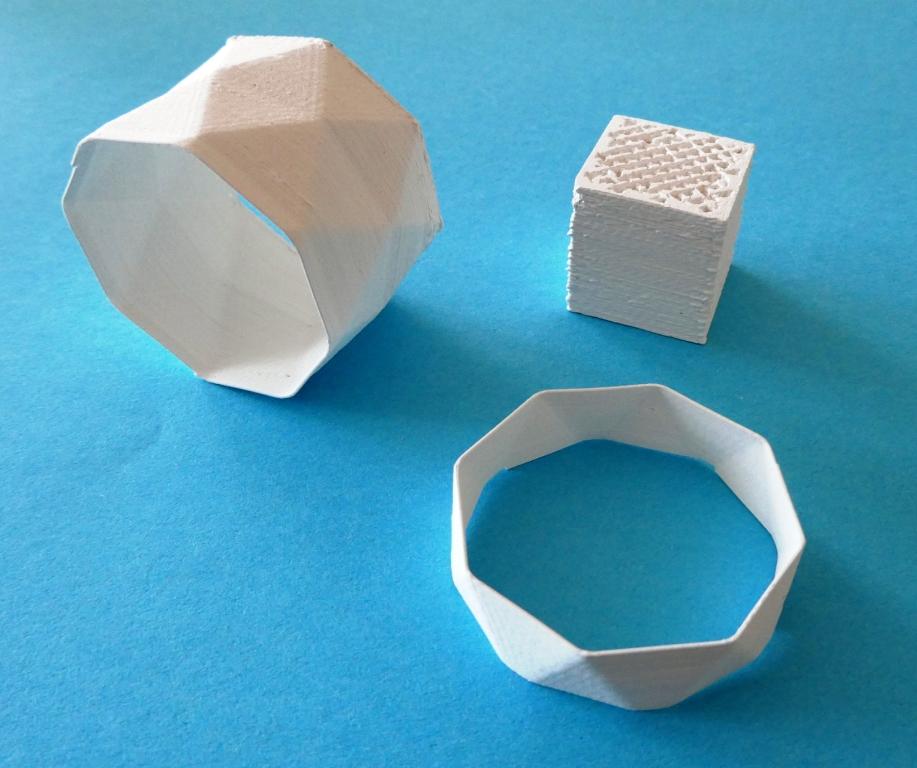

The range of materials covered includes both oxide and non-oxide ceramics, glass ceramics as well as stainless steel, HS steel and other P/M materials and intermetallics (tungsten carbide). Complementary small-scale production of selected components based on above materials

is also performed. Sales representation for complementary machinery for deliveries of complete

turn-key production lines is part of the business concept. Competitivity of our production & technology systems is ensured by combining low-cost investment, easy prototyping, minimized energy consumption and maintenance, low cost mould tooling, fastest possible start-up of production and environment-friendly technology as well as after-market technical service.

GOCERAM current business model

The most comprehensive sales deals are as complete packages, the whole package includes machines + specific production technology knowhow license (a kind of "cooking book") for all the production steps + commissioning/installation. Frequently, a prototyping and/or test production run is performed at shared cost prior to order.

The company has a dedicated R&D and application center where the novel processing is developed and validated. This more than 200 sq.m. facility contains a combination of modern office space,

meeting facilities and a state-of-the-art Prototyping & Application Center for customer training, engineering, and process development. It has a complete machinery line for general familiarization with the relevant MEDPIMOULD® processing steps. All the machinery manufacturing, electronics etc is subcontracted to a network of small and medium-sized companies with top competence in the respective engineering fields. We also have selected tooling suppliers with a good track record in Shenzhen (China) as well as verified Chinese suppliers of complementary equipment (in particular sintering furnaces).